Company

Manufacture

From the idea to the design, from the selection of materials to production, all the way to quality control and delivering the finished product, each step is carried out and kept under control internally.

Compab offers personalized solutions and boasts an optimized manufacturing cycle.

A flexible management system and timely delivery are part of the company’s modus operandi.

IDEAS

Ideas come to life at Compab.

Thanks to the company’s all-round view of the product and its use, ideas are taken from the manufacturing market and turned into designs. Then these ideas go to the manufacturing area to become finished, functional bathroom furnishings.

DESIGN

Design is the first step. Ideas are developed by the technical office, which then compares notes with the manufacturing department in order to create a marketable product. Once a prototype is made, the product is tested and refined until it is ready for the market. At that point, it is assembled and delivered to the client.

OPTIMIZATION and PERSONALIZATION

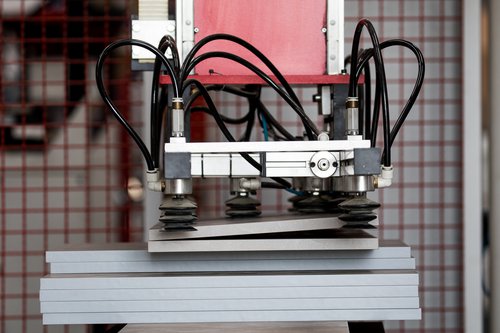

Compab is a semi-automatic company.

The manufacturing cycle is set up to optimize the production of bathroom furniture.

The cycle is controlled step by step and has been conceived to allow for elements to be finished without slowing down the entire manufacturing cycle. We like to think that the human factor makes the most of our semi-automatic production, and the results confirm this.

ATTENTION TO DETAIL

Compab products stand out for their use of high-quality new materials, for accessories that have been carefully conceptualized and for the use of trendy colours. Each detail is handled with care in order to achieve excellent results.

Compab bathroom solutions are modular. This allows us to expand or modify the composition of bathroom furniture, adding new, personalized elements at any time.

Compab makes every product unique in perfect Italian fashion.